Typically, the operations suite in an accounting system includes three main modules – Inventory Control, Order Entry and Purchase Orders. I like to classify these modules as action modules vs. support modules.

There are two “action modules” in an operation suite and one “support module” that enables action modules to perform. The action modules are Order Entry and Purchase Orders. The support module is Inventory Control.

THE ACTION MODULES

Users process sales orders through the Order Entry module. Order processing functionality is critical to most enterprises because it allows the company’s stream of life – the revenue stream – to flow.

Users control the purchasing of products for resale by using the Purchase Order module. This end of the operations process is also critical. If users handle the purchase process effectively, they can maintain adequate stock to meet customer demands. Purchasers also utilize this module to maintain supplier details and control supplier transactions.

When we think of our business processes, we naturally think of actions – processing sales, purchasing product, shipping product and handling adjustments. In our haste to get to the actions, we can sometimes neglect the importance of the support modules. We must consider what a smooth-running operations suite provides by asking some key questions.

Can customer service representatives be confident that items are priced correctly for a particular customer? Can they be sure that sales prices are accurately reflected? Can purchasers be comfortable that product costs will be accurately recorded in the item records? Can they rely on the system to alert them when quantities are getting low?

If we want to answer yes to these questions we must spend time setting up the Inventory Control module correctly.

THE SUPPORT MODULE

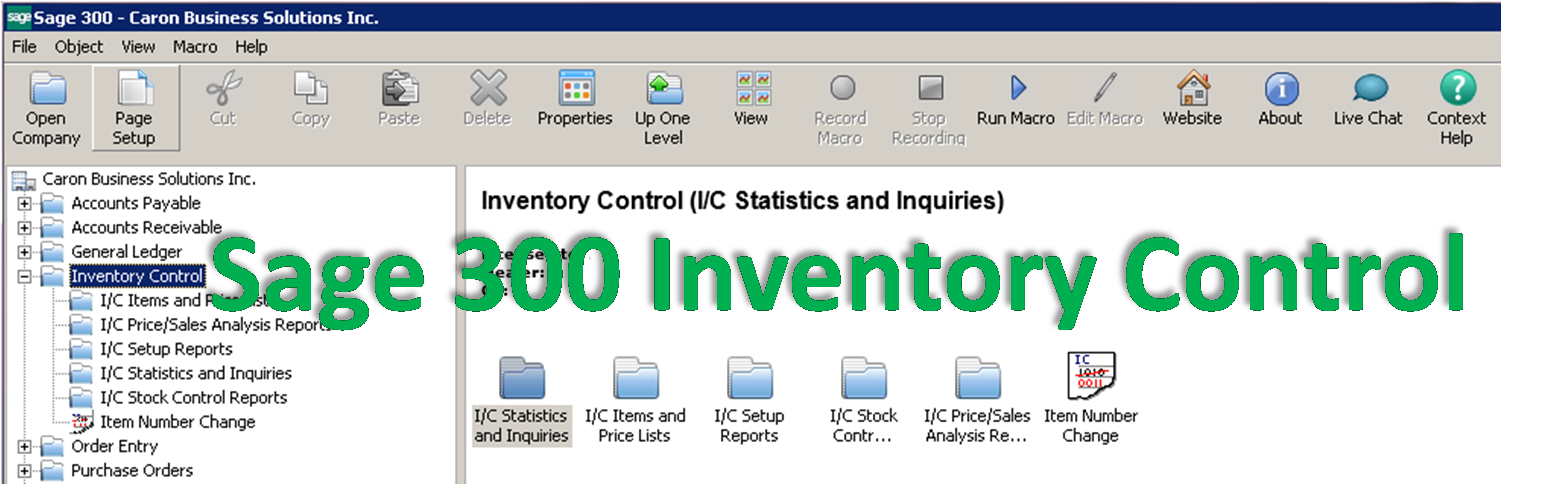

The Inventory Control module is critical to the smooth processing of an organization’s operations. It must be properly configured if the sales processing actions and purchase procedures are to be used effectively. This article explores some key components of the Inventory Control module.

Item Design

Although it seems obvious that item codes should be designed properly for an efficient and effective sales operation, this step is often neglected. The reason is that proper item design can be difficult. Thankfully, modern accounting software like Sage 300 provides many options in this area. In addition to the core item number, users are able to include customer item numbers, manufacturers’ product codes and supplier item codes. System designers can reap huge benefits in sales and purchase processing when they take the time to define items carefully.

Pricing

In a perfect world, there would be a single price for every one of our products. In the real world, there are multiple issues that have an effect on our selling price. The Inventory Control module must provide flexibility to support the sales process. An effective Inventory Control module will support many different price lists, volume and customer-based discounts, sale prices, currency-based pricing and contract pricing. When a system designer takes the time to set up pricing properly, the Inventory Control module will provide essential information to the order processing system

Costing

Did you make a profit this year? Did you make money this month or how about on this particular sale? Any business needs to know the profit on their products or services. In a competitive sales environment, customer service or sales personnel can only negotiate well if they know the bottom line, if they know how aggressive they can be on pricing. Businesses maintain costing in the Inventory Control module. Therefore, it is essential that that module has the ability to handle costs and adjustments from purchase transactions as well as currency issues, shipping costs, import duties and other issues that determine true landed cost. In order to truly support the purchase transactions, system designers must ensure that the Inventory Control module is set up to handle costs effectively.

Counts and Adjustments

Periodically, adjustments are required to quantities, costs or both. There are many reasons for this including annually inventory counts, shrinkage, mass price changes, value write-downs and processing errors. Users can process these adjustments easily if the Inventory Control module has the necessary functionality for adjustments and it is set up properly. A poorly configured Inventory Control module can make this process very difficult.

Summary

It’s always nice to think about actions when implementing operations software for your company. The thought of efficient and profitable sales transactions and a well-oiled supply chain is an exciting thing to plan for. Put a lot more thought to setting up the Inventory Control module than you might think necessary. It will help you realize your dreams and profit and efficiency.